Our portfolio of particle sizing instruments for better particles

Sympatec develops, produces, sells and supports a portfolio of outstanding instruments for the analysis of particle size and particle shape, in laboratory and process applications. We use constant innovation to make a striking contribution to the development of sustainable and powerful sensor technologies, product-appropriate dispersing and dosing systems, and sampling procedures that are adapted to processes. We offer high-performance, proven system technologies for the reliable characterisation of dry and wet disperse particle collectives such as powder, granules, fibres, suspensions, emulsions, gels, sprays and inhalants with particles ranging in size from under one nanometre to over 30 millimetres.

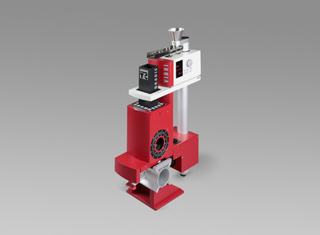

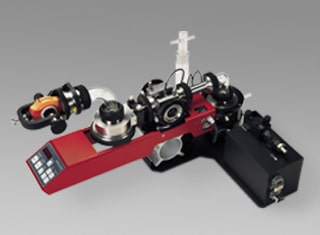

Our instrument portfolio is based on the four underlying sensor technologies of laser diffraction, dynamic image analysis, ultrasonic extinction and dynamic light scattering with photon cross-correlation spectroscopy. The physical measuring principle has a decisive influence on the instrument design. We maintain a modular system architecture that can be adjusted flexibly for each application as appropriate to the product, so that the products to be investigated do not require elaborate sample preparation in order to fit with the system. Our aim is the measurement of particle systems in their original state. This is achieved through a wide range of dispersion systems and dosing unit options for our HELOS laser diffraction, and dynamic image analysis with QICPIC. The sensor is the heart of the measuring system. Its optical bench defines the integration concept for optional changeable lenses, dispersers and dosing units. The evaluation and management software, which integrates and manages all system components as well as the peripherals, is also part of the central system architecture. Our powerful application software is the shared platform for all the sensor technologies in use.

Our systems are used worldwide in scientific and industrial fields of application

- In quality control on disperse particle systems | From incoming goods to the end product

- In product and method development

- At all stages of “scaling up” of methods and process engineering | From laboratory to production scale

- In controlling and managing unit operations.

All the instruments provide reliably high-precision, reproducible, and comparable results, with very short measuring times. The use of the same measuring principles ensures excellent particle measurement result comparability between laboratory and process applications.

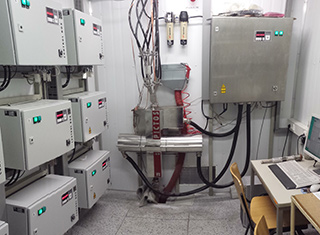

Installation environments

Our portfolio contains instruments for both traditional laboratory operation – which are used as individual position applications – and integrated systems that can be incorporated into laboratory automation or process control systems. All the measurement systems feature a certain level of modularity, enabling the system configuration to be ideally adapted to the measurement task, specific product features, or process requirements. The possible types of installation differ in particular with respect to the type of sampling, sample preparation, and sample feeding, as well as measurement frequency and the similarity or variability of the samples to be measured – along with closeness to the process both physically and in terms of timing. The spectrum ranges from traditional laboratory analysis (off-line), in which the sample is fed in manually; to solutions in central production laboratories and automated sample infeed (at-line); to real process analysis in which the system is connected directly to the process (on-line); or directly into the line carrying the product, or a reactor (in-line).