Powerful dry dispersion in the free aerosol jet for laser diffraction and dynamic image analysis

RODOS is the original by the inventor of dry dispersion. With this breakthrough innovation, Sympatec has opened up dry applications to particle measurement technology – as early as 1982. Since then, it has been possible to dry measure powders, fibres and granules in a manner appropriate to the product , with both laser diffraction and dynamic image analysis. No other method of dispersing is anywhere near as powerful or achieves such an efficient as well as gentle dispersion from the submicron to millimetre range. The speed, reproducibility, comparability and (above all) the high statistical reliability with large sample volumes up to more than 1,000 ml are particularly striking. However, even the smallest particle quantities in the microgram range are fully recorded with sophisticated trigger algorithms.

The reliable dispersion determines the validity of the size analysis – especially for collectives of fine, dry and cohesive particles. The principle of RODOS dry dispersion with an upstream dosing unit and a powerful compressed air injector ensures the effective and product-specific dispersion of solid particles in a size range of less than 0.1 microns to 4,000 microns. Dosing initially generates a constant mass flow. Subsequently, dispersion forces tailored to the product ensure an effective separation of the particles that are fed to the sensor in the aerosol jet as single particles. This is achieved just as reliably for fine, highly agglomerated particles as for the gentle dispersion of metastable and coarse particles.

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Principle of RODOS dry dispersion

The dispersion effects in the RODOS injection disperser are caused by a special flow control in the long, straight dispersing line that ultimately enables a release of the isolated and highly accelerated particles in an aerosol jet. The product is fed in the axis of flow and initiates linear acceleration and mixing of particles with the compressed air or an inert gas. The dispersion energy is precisely adjusted to the product via the pre-pressure and an annular gap. The high air flow, the expansion and the ultimate jet formation provide a high exit speed of up to 100 m/s and an optimum optical dilution of the aerosol cloud for analysis. This way it is also possible to supply the sensor with difficult-to-disperse particles, such as residually moist, oily or magnetic powder, as perfectly dispersed individual particles without the risk of reagglomeration.

The basic dispersion effects are composed of speed gradients (turbulences) in the air flow as well as particle-particle and particle-wall impacts. The method we have developed for dry dispersion with compressed air has not only found its way into the applicable standards (cf. ISO 13320 – laser diffraction), it has also firmly established itself on the market and, with RODOS, sets the standard for all dry, fine and agglomerating products.

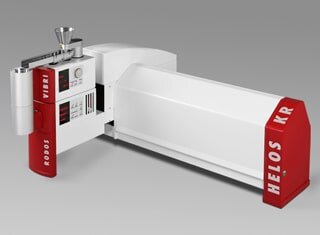

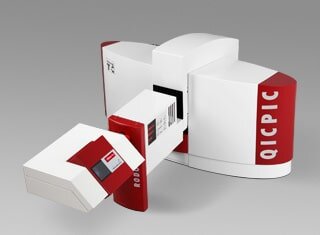

Various RODOS versions are available for combination with both HELOS laser diffraction and QICPIC image analysis. The modularly interchangeable dosing systems VIBRI, ASPIROS and MULTISAMPLER are used for product-oriented particle supply. The method of dry dispersing is successfully used with the proven RODOS core technology in many applications in our process analysers for laser diffraction with MYTOS and for dynamic image analysis with PICTOS. Dispersion routes with suitable internal diameters are recommended for an optimal adaptation of the RODOS dispersion for the particle size of the respective product.

RODOS | Models

RODOS is available in two basic models. The manual operated RODOS classic can only be used in combination with HELOS laser diffraction and is the best choice for repeated measurements of the same product while retaining all dispersion parameters. The most recent stage in the evolution of dry dispersion is the fully automated, modular RODOS/L family for versatile use in laser diffraction and dynamic image analysis.

The classic RODOS with manual adjustment of the dispersion parameters is ideally suited for individual product applications and applications where the measuring parameters remain constant. The precisely reproducible measurement conditions of flash dispersion form the basis for reliable, repeatable measurement results. Simple access to parts that are in contact with the product – particularly the dispersing line – permits quick and easy cleaning and maintenance by the user.

The RODOS dry disperser in its original version with a turntable is available for more demanding dosing tasks. The turntable doses particularly uniformly with a groove for collecting and conveying the product, a wiper, roller and pick-up brush – for a continuous mass flow. Products that are easier to dose are directly fed into the RODOS funnel with the VIBRI vibration chute – the turntable mechanism is an optional feature.

typical configurations

The L-series consistently evolves the strengths of the proven RODOS dry dispersion and in its most recent stage of evolution offers a particularly resistant dispersing line and a modular design. With its new handy and compact design, the disperser is optimally tailored to the requirements of HELOS laser diffraction and QICPIC image analysis. Perfectly reproducible measurement conditions are ensured for any application thanks to the automatically positioned dispersing line.

The dispersing system can be controlled either using software or the manual control panels. Upon request, the application software saves all dispersion parameters as retrievable measurement methods (standard operating procedures (SOPs)). In this way, measurements are reliable and independent of the operator, even if the product and/or application is changed frequently. The dispersing line’s feed rate, dispersing energy and position are precisely and fully automatically reproduced. The permanent monitoring of the pressure conditions in the intake and exhaust tract are ensured through the reliable promotion of the sample material. RODOS/L is therefore also ideally suited for validated pharmaceutical applications.

The service life of the dispersing lines is increased further by using micrograin tungsten carbide in the injector assembly. The high-performance material used is twice as hard as hardened tool steel. The longer tool life is particularly noticeable when measuring highly abrasive materials – as in refractory materials, cement or abrasives.

The modular lightweight construction and mechanical fast-locking systems allow for easy handling and – if necessary – a quick changeover of the dispersing system in the sensor. If frequent changes between dry and wet dispersion are required then the RODOS/L is optionally available with the tried-and-tested wet dispersion unit SUCELL/L as a combined dry and wet dispersion unit OASIS/L.