True-to-method laser diffraction with versatile dry dispersion for fine dry and even cohesive powders from 0.1 µm to 875 µm

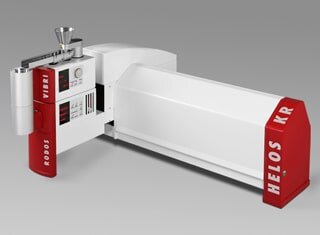

Together with the powerful and fully-automated dry dispersion unit RODOS/L, the compact laser diffraction sensor HELOS/BR offers fast and repeatable particle size analysis for dry, fine-grained products ranging from 0.1 µm to 875 µm. Agglomerative, cohesive powders are also reliably dispersed and measured.

All measurement and dispersion parameters are software-controlled and can be saved as retrievable measuring methods (Standard Operating Procedures (SOPs)). In this way, measurements are reliable and independent of the operator, even if the product and application are changed frequently. Feed rate, dispersion energy, position of the dispersing line and the trigger for the measurement can be reproduced accurately and fully automatically. The dosing of the powder sample is performed via the precision vibratory feeder VIBRI/L, which guarantees optimum concentration of the sample in the measuring zone with a uniform, controlled product supply. The perfectly coordinated combination of sensor, dosing and dispersion enables a gentle, product-specific and precise particle size analysis far into the submicron range.

The modular concept of the HELOS laser diffraction series allows this configuration to be systematically expanded with numerous dispersion units and dosing options to open up many more measuring applications. If frequent changes between dry and wet dispersion are required, the RODOS/L is optionally available with the proven wet dispersion unit SUCELL/L as a combined dry and wet dispersion unit OASIS/L.

- Particle size and particle size distribution

- For dry, fine-grained and also cohesive powders

- For analyses in the quality or production laboratory | Also process-oriented

- Sample amount per analysis < 1 mg to 1,000 g

- 5 high-resolution measuring ranges from 0.1 µm to 875 µm | R1 to R5T

- True-to-method measurement performance for changing measuring tasks

- Automatic adjustment of all dispersion parameters | Software-controlled

- Upgradable to combined dry and wet dispersion system OASIS