Dry or wet dosing system in fully automatic batch mode

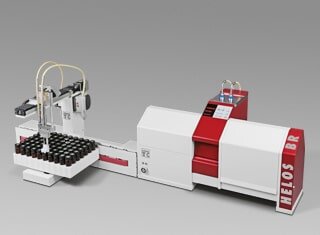

MULTISAMPLER has been developed for users having high sample throughtput with one disperser and one sensor. The fully-automated handling robots MULTISAMPLER/dry and MULTISAMPLER/wet master dry and wet applications. They are used for particle sizing with laser diffraction sensor HELOS and for particle size and particle shape analysis with image analysis sensor QICPIC.

Up to 70 sample vials, each containing up to 39 ml, are fed out of a rack to the sensors. The single samples are identified by laser engraved DataMatrix codes. This enables a direct assignment of dispersion and measuring procedures by software, if necassary different for each sample. For the optimum protection of the sample, the vials are made of brown borosilicate glass. They are reusable, as the DataMatrix code is laser engraved into a ceramic substrate. The vials are sealed by PTFE-silicon septum caps with nearly universal chemical resistance. If 70 samples should not be sufficient, the number can be doubled to 140 by using the Rack-Extension option.

If MULTISAMPLER/wet is used for samples to be measured in wet conditions, a specially designed sampler with a double injection needle is used. This instrument is able to feed particles up to 1 mm in diameter. This will ensure that the complete sample is analysed. The septum-caps prohibit a contamination of the environment by the sample or the dispersing media. If appropriate cleaning-cycles are added to the control-program and a switch of the dispersing media is possible offering a flexible adaption to the application.

MULTISAMPLER/dry is best suited for dry samples in combination with dispersers of the RODOS family. In this case a specially designed sampler uses the vacuum generated by RODOS to fluidize and transport the sample. Particle sizes up to 1.5 mm are possible. Again, the special shape of the V-vials in combination with a cyclone-like sampling nozzle enables an almost complete emptying.

Sample transport and sample handling are performed by precise servo drives. As handling times of only some seconds are achieved large numbers of samples can be analysed with nearly no idle-times.

A fully automatic sample handling system for high sample throughput is available with MULTISAMPLER. In batch operation up to 70 vials with 39 ml volume each are fed from a tray into the system. Sample identification is achieved with a data matrix code etched to the bottom of the glasses. The complete amount of sample is captured into the airflow of the RODOS injector, dispersed in a free jet and measured by the laser beam.

The combination of QUIXEL and MULTISAMPLER supports efficient laboratory analysis with high sample throughput. The system can run up to 70 sample glasses with 39 ml each without operator input. The glasses, which are sealed with silicone septum, carry a data matrix code for sample identification. Two peristaltic pumps operate simultaneously to fill and empty the vial.