Determination of the pigment properties of calcium carbonate by particles size

Calcium carbonate is a commonly occurring mineral that is present in many rocks such as limestone and marble, as well as in the skeleton of stony corals, and is immensely versatile. In the construction industry, calcium carbonate is used as a raw material to produce lime cement and burnt lime or even as a solid block. In coal-fired power plants, it is used for flue gas desulphurisation and as a basic material for plaster production. Moreover, calcium carbonate is used as an additive in steel production, in fertiliser production and as a pigment in the paper and paint industries.

The required product characteristics, which are largely defined by their particle size distributions, are just as varying as the areas of application. A pigment obtains, for example, its maximum colour effect only in a narrow particle size range below 1 to 2 microns. However, the storage stability of pigment suspensions is also determined by the particle size. Whether produced mechanically by grinding or wet-chemically through precipitation, in each case the particle size distribution is a decisive quality criterion that should be continuously monitored where possible to ensure compliance. Here, the laser diffraction has a significant effect on quality assurance with its high-resolution measurement with analysis times of typically less than one minute.

- Determination of pigment properties such as colour effect, suspension stability or processability by particle size

- Optimisation of time- and energy-intensive grinding processes

- Setting the storage stability of pigment suspensions

Download application note for detailed information

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Application strengths

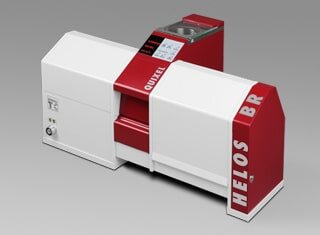

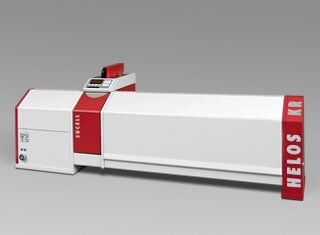

- Short analysis times of a few seconds

- High-resolution particle size distribution

- Unmatched repeatability with equally high sensitivity

- Automatic dilution to working concentration

- Automatic detector focusing

- Flow-optimized wet dispersion ensures homogeneous sample management

- Rapid emptying and automatic filling of the wet dispersion unit

- Quick and automated cuvette access for easy cleaning

Customer benefits

- Specifiable product quality

- High product valence

- Optimisation of grinding time and cost reduction

- Timely quality inspection of the product properties

- Increase in product throughput

- Reduction of waste material