Particle size analysis for suspensions and emulsions from 0.1 µm to 875 µm with fast, fully automated measuring cycles

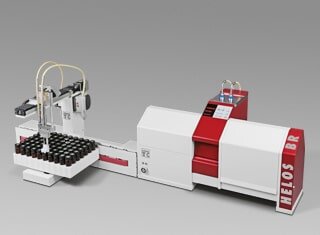

Together with the powerful and fully-automated wet dispersion unit QUIXEL, the compact laser diffraction sensor HELOS/BR offers fast and reproducible particle size analysis for finely dispersed suspensions and emulsions from 0.1 µm to 875 µm. Equipped with a stainless steel basin, centrifugal pump, tubeless measuring circuit and interchangeable flow cuvettes, QUIXEL is the first choice both for standard analyses and for complex measurement tasks. The basin geometry and the flow control guarantee a stable suspension and minimise the risk of sedimentation even in cases with broad distributions and particles with high density.

All measurement and dispersion parameters can be entered using the operating panel or the software and be saved as retrievable measuring methods (Standard Operating Procedures (SOPs)). In this way, measurements are reliable and independent of the operator, even if the product and application are changed frequently. The pump speed, ultrasonic treatment, possible temperature control and the trigger for the measurement can be reproduced accurately and fully automatically. Optional lids with corresponding tube connections are available for further automation of the supply of additives and the rinsing processes.

In the QUIXEL basin a precisely controllable ultrasonic generator and the centrifugal pump ensure reliable dispersion and mixing of the sample. The optimally dispersed suspension or emulsion is fed as a representative sample flow to the measuring zone. Flow-optimised cuvettes with layer thicknesses of 2 mm and 6 mm enable flexible adaptation to the relevant application. Different gasket materials are available to ensure that the chemical resistance is matched to the product and dispersing fluid (FKM, EPDM or FFKM). Thanks to the lowerable bottom of the basin, quick draining and cleaning are possible in just a few seconds even with high-viscosity dispersion media. Equipment options with internal or external heating and external cooling open up a wide range of applications.

Application in automated laboratory environments

The HELOS system can be integrated in an automated laboratory via various interfaces. The control and evaluation software typically receives an ID and a time stamp for a sample from the control system. Based on this, the system calls up a measurement specification, adjusts the measuring and dispersion parameters fully automatically, performs the measurement and reports the results of the measurement back to the control system. In this way, remote controlled measurements can be performed self-sufficiently in automated operation even if there are frequent product and grade changes.

- Particle size and particle size distribution

- For suspensions and emulsions

- For analyses in the quality or production laboratory or automated laboratory

- Variable analyses volume from 300 ml to 1,000 ml in a closed loop

- 5 high-resolution measuring ranges from 0.1 µm to 875 µm | R1 to R5T

- True-to-method measurement performance for changing measuring tasks

- Automatic adjustment of all dispersion parameters | Software-controlled

- Integrated sonication | Energy input 0 to 60 W

- Heating and cooling options | Temperature-controlled from 0°C to 60°C

- Tubeless measuring circuit for high resistance and fast measuring cycles

The modular concept of the HELOS laser diffraction series allows this configuration to be systematically expanded with numerous dispersion units and dosing options to open up many more product-appropriate measuring applications.