Online particle characterisation in process applications

Controlling and managing processes in real-time is the most effective way to ensure high-quality production with optimum use of resources. The application of process measurement technologies guarantees close control of critical, quality-relevant process parameters, and also enables prompt interventions into the process. In this way, you can reliably fulfil your production specifications while avoiding waste or off-specification batches, which must either be disposed of or reworked at great cost. This enables you to avoid inefficient process management beyond ideal operation. The pharmaceutical industry has set out the requirement for in-process controls in its Quality by Design initiative, with the aim of enabling production processes to be better understood, and ensuring ideal management of those processes. Quality should not be reviewed in a product retrospectively, and instead should be ensured right from ongoing production, through the use of appropriate production facilities and prompt online process control.

In-process control with the aid of physical parameters such as particle size or particle shape may be achieved in a variety of ways. In principle, three equally important components of process analysis are key to obtaining valid and meaningful measurement results:

- representative sampling in processes

- product-appropriate dispersion of the sample taken

- sensitive sensors for recording and evaluating the sample

Possibilities offered by process connection

Furthermore, process integration options differ with respect to the type of sampling and sample infeed, closeness to the process both physically and in terms of timing, and the frequency of measurements. Our analytical systems can be connected to the main process flow with different levels of integration. The spectrum ranges from traditional laboratory analysis (off-line), in which the sample is fed to the measurement instrument manually; to solutions with central production laboratories and automated sample feeding (at-line); to real process analysis in which the system is connected directly to the process (on-line); or directly into the line carrying the product or a reactor (in-line).

in-line particle sizing

Sampling and the analytic unit are fully integrated into the main process flow. With ultrasonic extinction with OPUS, the measurement is taken directly in the main process flow, or in a reactor under process conditions. With optical procedures – such as laser diffraction with MYTOS – it is necessary to adjust the optical concentration to the sensor after sample splitting. The dispersion used to achieve this takes place directly before analysis in the main process flow. The product remains in the process line for constant real-time measurement; only the measurement data leave the process.

on-line particle sizing

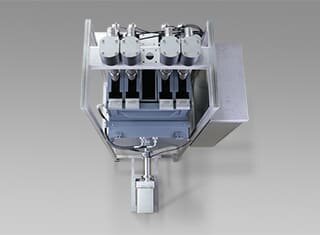

The measurement system, consisting of a dispersion and sensor unit, is operated in the bypass to the main process flow. The product sample is removed from the process flow via a sampling system, fed to the measurement system, and measured in real-time on a quasi-continuous basis. The product may either be returned to the process flow, disposed of, or recovered for other purposes.

at-line particle sizing

Discrete samples are removed from the production flow and fed to an independent measurement system consisting of dispersers and sensors. An indirect, automated process connection with predominantly constant measurement requirements is in line with the concept of laboratory automation.

Innovative particle sizing technologies for particle analysis in process environments

Most of our sensor technologies and disperser systems proven in laboratories are also available for use in processes or automated laboratories. The use of the same components in our laboratory and our process systems ensures a high degree of comparability in the measurement results for particle size and particle shape, and therefore supports all measurement requirements from product development to volume production at an industrial scale. The powerful control and evaluation software also offers all the required options for integration into a control system, and is suitable for establishing system control based on real-time data.