Real-time particle size measurement from below 0.1 µm to 3,000 µm in suspensions, emulsions and slurries with ultrasonic extinction in process or bypass lines from DN10 to DN25

The robust ultrasonic extinction sensor OPUS is integrated via a flow-through adapter in process lines or in bypass lines with diameters of 10 mm to 25 mm and monitors the particle size distribution in continuous real-time analysis and the concentration of suspensions and emulsions in a range of below 0.1 µm to 3,000 µm. The acoustic measurement method offers outstanding capabilities for in-line and on-line measuring, even in highly concentrated media. Using sound waves means that analyses can be performed in their original state regardless of the transparency of the material system – without dilution and under process conditions. The continuous measurement value acquisition enables optimised process control and quality control in wet grinding circuits, classification and in mixing and emulsifying processes as well as in crystallisation, polymerisation and particle synthesis.

The ultrasonic extinction allows for an extremely robust design with a finger probe that withstands a temperature range of -20°C to 120°C, high pressures up to PN40, aggressive media and abrasive product streams. All components coming into contact with the product are adapted to the respective conditions and are designed in resistant materials: Finger, measurement zone and stainless steel housing (type 1.4571 | type 1.4539 optional) or highly corrosion-resistant nickel-chromium-molybdenum alloy (Hastelloy® C-22, type 2.4602), acoustic windows made of vitreous carbon (Sigradur®) and seals made of EPDM, FKM (Viton®) or FFKM (Kalrez®). When required, sensor cooling with compressed air is available for continuous operation at high process and ambient temperatures. Safe operation in hazardous areas (ATEX) is ensured through an optional overpressure enclosure.

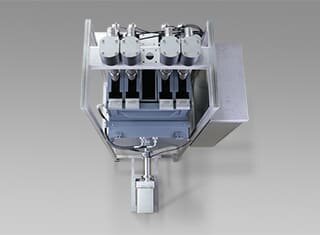

Suitable flow-through (FT) adapters are used for the installation of the OPUS measuring probe in smaller pipe diameters from DN10 to DN25. These adapters guide the entire product flow through the sensor measurement zone under continuous flow conditions. This makes it possible to analyse particle size and concentration in smaller production scales, bypass lines or pilot plants with flow quantities up to a maximum of 2,000 l/h in real time. As a function of the flow rate and the measuring gap that can be adjusted from 1 mm to 10 mm, an analysis volume of up to 1,000 l/h is recorded.

The FT adapter consisting of two half shells is attached to the measuring finger so that the adapter is flush with the openings of the OPUS measuring gap. The system is integrated in the production line at an installation height of 300 mm via the standard flange of the FT adapter. The adapter variants FT10 | FT15 | FT 20 | FT25, which correspond to the respective nominal diameters of the flange connections, are available for various installation requirements. Due to the small pipe cross-sections, providing the OPUS-FT system in the optional standby (SB) rack is recommended.

The OPUS system can be flexibly incorporated in a control system using common communication standards such as Modbus® RTU, Modbus® TCP, Profibus®, OPC (Open Platform Communications ), TCP/IP, FTP or analog PLC signals in order to set up the remote-controlled or autonomous carrying out of measurements. The information gained in real-time about the particle size distribution and the concentration are provided to the process control system for process monitoring or for process control.

Individual, customer-specific adaptation to the existing process environment and to the products that are to be measured takes place in close cooperation with the customer's process engineers and is accompanied by our experienced engineering team. Special equipment for potentially explosive areas (ATEX) is, of course, also part of our portfolio. We are also happy to provide alternative flange connections or pressure levels for the FT adapter upon request.

- Particle size, particle size distribution and concentration

- For suspensions, emulsions and slurries with particle concentrations up to 40 volume percent

- Product temperatures from -20°C to 120°C | pH values from 1 to 14 | Pressure level PN40

- For continuous real-time analyses in the process | in-line and on-line

- Highly resolved measuring range from < 0.1 µm to 3,000 µm | 31 measuring points

- For installation in pipelines from DN10 to DN25 with flow-through adapter

- Measurement under process conditions | No product removal or sample preparation

- Connection to process control systems | Modbus®, Profibus®, OPC, TCP/IP, SPS signals

- ATEX optional

- Standby rack recommended