Particle size and particle shape with dynamic image analysis

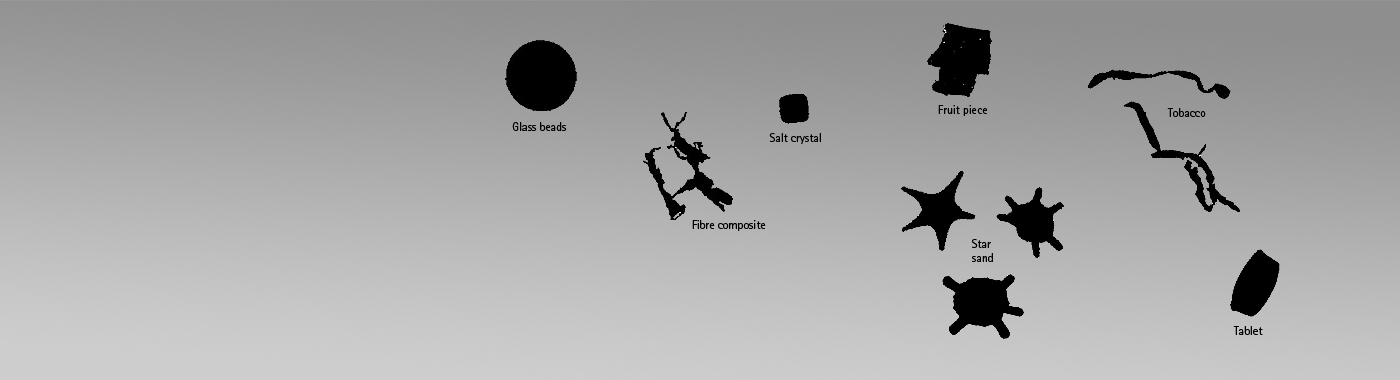

With laser diffraction the particle size distribution is determined by the characteristic diffraction pattern of a particle collective. In contrast, image analysis captures the physical properties of each single particle. The distribution of a property such as size or shape descriptor can thus be resolved in nearly any class. With image analysis even smallest amounts of over or under sized particles may be detected. Even single particles with specific geometric properties such as aggregates, fractures or foreign particles are traceable.

Image analysis operates in a similar way to a modern microscope: a digital camera with special optics captures the particles within the frame. Physical information about particle properties is transmitted to a computer. For each single particle in the image size and shape descriptors are determined by evaluation software.

For the characterisation of real particles the particle shape becomes more and more important in addition to particle size. Image analysis can give valuable service. For particle size and shape analysis following topics are of decisive importance:

- Image Analysis is dealing with number statistics. The minimum number of particles can be estimated in terms of the maximum error of the Q0(x) distribution as nmin > 1/E²max. This results in more than 10,000 particles for a maximum standard deviation of 1%. Often a volume based result Q3(x) is requested. Following ISO 14488 the minimum number of particles is now depending of the size distribution itself. Typically more than 1,000,000 particles are necessary to reach a maximum error below 1%.

- The particles should be separated from each other. Otherwise time consuming algorithms would have to be used to separate the particles by software. Therefore, optimum dispersion of the particles is necessary.

- The measuring time should be kept within acceptable limits: Influential parameters are the number of particles per image (as many particles as possible without overlaps) and the frame rate.

- As the particle contour has to be detected precisely, the particles must be imaged with the highest possible contrast.

- The particles have to be oriented randomly. Otherwise the measured size distribution can be incorrect, as e.g. oval pellets lying on a flat surface would be represented always by their largest dimension, resulting in larger volume fractions.

Static Image Analysis

Particles are prepared on to an object slide with a fixed orientation, which may generate systematic errors. Particles are normally presented with their largest area facing the camera, with little clue as to the real shape. Depending on nature and preparation of the sample, dispersions may be poor with overlaying particles and hidden fine fractions.

The statistical significance of static image analysis has the most substantial limitations. The particle number is significantly constrained due to the limited size of the object slide leading to poor statistical analysis and larger error for broadly distributed particle collectives.

Dynamic Image Analysis

Considering dynamic image analysis the particles are streaming continuously through the measuring volume controlled by the camera. The free movement leads to random orientation of the particles. From the different perspectives their actual shape and size distribution can be accurately determined.

With a continuous feed of dispersed particles reliable and representative results are achieved based on a statistically significant number of particles. By closely controlling the concentration of the particle flow the overlay of particles is prevented.

Applying powerful algorithms the evaluation software provides all relevant size and shape descriptors within seconds after the measurement. Measures for length, width, equivalent circumference and diameter of a circle describe the size of a particle. Sphericity, aspect ratio and convexity provide information about the shape. Fibres can also be properly evaluated with length, diameter, straightness and elongation. All parameters may either be presented as distribution for the whole sample or individually for each single particle. A particle gallery with numerous selection and filter parameters supports the generation of specific and meaningful results.

Learn more about shape descriptors