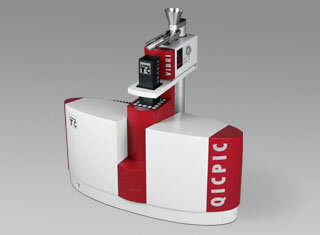

The universal shapefinder for particle characterisation ranging from below 1 µm to 34,000 µm

Applying components of highest performance our modular particle size and shape analyser QICPIC develops the full power of dynamic image analysis. High speed image analysis using a pulsed light source with illumination times in the nanosecond range the particles are optically frozen while a high-resolution, high-speed camera captures the razor-sharp particle projections with a frequency of up to 500 frames per second. With powerful algorithms QICPIC is evaluating millions of particles in shortest time and guarantees outstanding statistically relevant results. Numerous implementations in pharmaceutical and chemical industry, powder metallurgy, additive manufacturing, food and beverage technology or soil science just denote the array of applications in industry and research.

- Reliable and fast determination of particle size and particle shape as well as fibre characterisation

- Wide measuring range from < 1 µm to 34 mm

- Fully compliant with image analyses standard ISO 13322-1/2

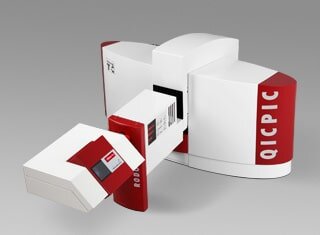

- Flexible adaptation to a wide range of applications by modular system design with a great selection of dispersing and dosing units for dry and wet applications

- Powerful evaluation modes | Meaningful results

- Adaptable, high resolution size and shape distributions

- High confidence level by fastest image acquisition allowing for a high number of particles

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Watch the QICPIC teaser video!

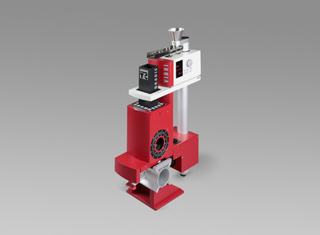

QICPIC/L Series

The QICPIC/L Series is winning with its new pulsed light source, improved image quality and an outstanding measuring performance for fines and dry products. The unrivalled, high speed RODOS dispersion empowers image analysis to master dry and even agglomerating powders now as fine as 1.8 μm and above. Most prominent features are reproducibility and comparability of measurement results at optimized sample quantities.

Each of the discrete, high resolution optical modules M3 to M9 unlocks a specific, wide dynamic measuring range within the unique overall detection range from 0.55 μm up to 34 mm.

| Sensor | Measuring range/ Modules | Frame rate/ fps | data rate |

|---|---|---|---|

| QICPIC/L02 | 0.55 - 33,792 µm/ 4 from 7 | 85 @ 4.2 MP to 225 @ 1.5 MP | 5 GBit/s (1xUSB 3.0) |

| QICPIC/L06 | 0.55 - 33.792 µm/ 4 from 7 | 175 @ 4.2 MP to 500 @ 1.5 MP | 10 GBit/s (2xCXP-5) |

Applying dosing and dispersing units of modular design for dry and wet products the particle sizer QICPIC is flexible to adapt to powders, granules, fibres, suspensions and emulsions. This ensures a product-specific characterization of particle size and particle shape parameters matching the true nature of the application.

Particle size analyses with image analysis sensor QICPIC guarantee a valid method transfer and perfect correlation with sieving results. While maintaining the defined quality criteria from sieving, a changeover to the powerful and versatile image analysis is a viable and worthwhile choice. In addition to the high resolution particle size distribution, the QICPIC analysis yields all relevant size and shape parameters for the characterization of most diverse particles. Our powerful PAQXOS application software offers everything in the areas of evaluation modes, shape parameters and volume-based particle models in order to achieve a perfect comparability to the classical sieve analysis. Furthermore a revalidation function on sieving analysis results is available.

Fast and reliable characterisation of free-flowing products – for instance in quality control or production – is best realised with a QICPIC sensor in combination with gravity dispersion in the GRADIS free-fall shaft. Compared to the elaborate analysis with a sieve stack, this is an efficient and more meaningful option. Reproducible and statistically sound particle size distributions with high resolution are practically achieved in real-time. To enhance your product insights, image analysis additionally provides illustrative shape information.

Especially developed optical set-up sets the standards for precision of the particle measuring results. The particle outlines, generated in a parallel beam, are imaged with telecentric optics practically free of aberrations and with highest contrast – even for transparent particles. The camera precisely captures the particle projections with 256 greyscale intensities and a resolution of up to 4 megapixels. The raw data is transmitted to the computer for storage and evaluation with transfer rates up to 25 gigabit per second.

Applying powerful algorithms the evaluation software provides all relevant size and shape descriptors within seconds after the measurement. Measures for length, width, equivalent circumference and diameter of a circle describe the size of a particle. Sphericity, aspect ratio, convexity and many more parameters provide information about the particle shape. Fibres can also be properly evaluated with length, diameter, straightness and elongation. All parameters may either be presented as distribution for the whole sample or individually for each single particle. A particle gallery with numerous selection and filter parameters supports the generation of specific and meaningful results. With the recorded particle video stored in the data-base the complete measurement can be viewed retrospectively.