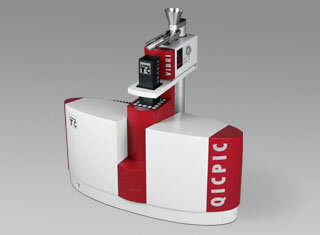

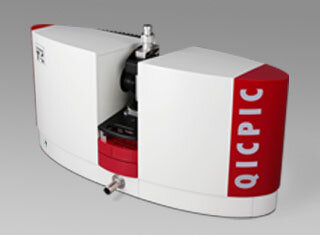

Particle characterisation in the laboratory

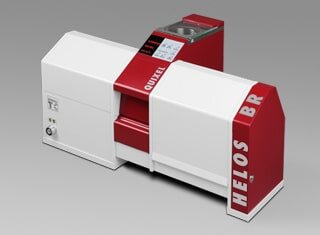

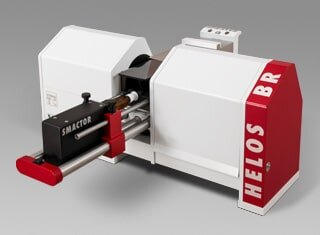

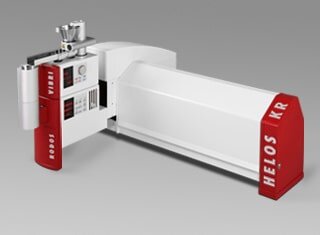

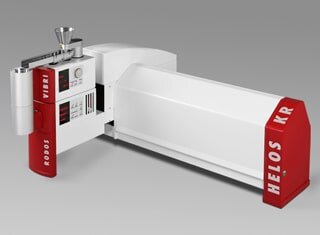

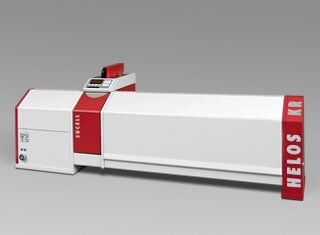

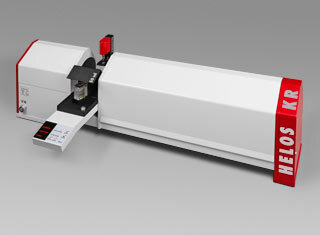

The analysis of physical parameters relating to product development, quality control and process monitoring has become an integral component of the work performed by many laboratories. Recording the distribution characteristics of particle sizes and particle shapes of disperse systems is of central importance in this process as, in many cases, they significantly influence the final product characteristics, and product quality, as well as processing, transport and storage behaviour. Proven technologies in reliable measurement systems, featuring a modular structure that can be adapted to the needs of the samples to be investigated, provide reliable measurement results. Our sensors record and analyse interactions between particles and optical or visual waves, based on innovative technologies such as laser diffraction, dynamic image analysis, ultrasonic extinction, and dynamic light scattering. The measurement results are clearly prepared in distribution charts or tables, or as individual characteristic values, and very quickly provide the user with the information they need in terms of quality and process control.

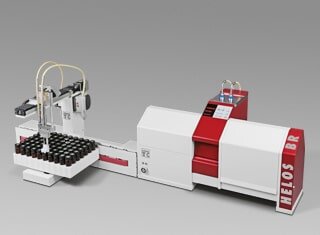

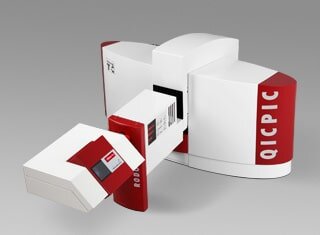

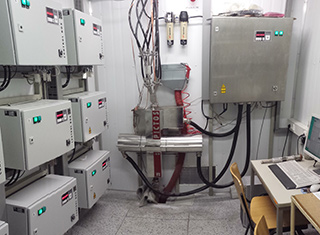

Particle characterisation in the automated laboratory

If there are several points in a process that need monitoring, a central laboratory in combination with sampling and sample transport systems is an efficient solution for automated control of complete production lines. The interface to our measurement systems is implemented by sample preparation and distribution which are automated by conveyor systems and robots.

Typical applications in the laboratory comprise dry powder, granules, fibres, suspensions, emulsions, gels, sprays and inhalants, ranging in size from 0.5 nm to 34,000 µm. The modular instruments can be adapted to specific applications in a variety of ways. All the instruments provide reliably high-precision, reproducible, and comparable results, with very short measuring times.