High-performance laser diffraction for dry, adhesive powders ranging from 0.1 µm to 3,500 µm without cross-contamination

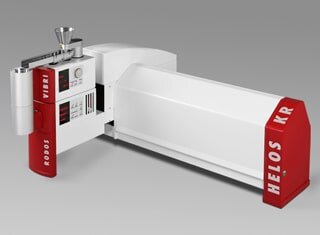

With the long optical bench, the HELOS/KR laser diffraction sensor covers a particularly wide particle size range. In combination with the fully-automated RODOS/L dry dispersion unit and the self-cleaning dosing unit VIBRI/R, this configuration offers fast and reproducible particle size analyses for dry, dispersed products in the range from 0.1 µm to 3,500 µm. Reliable dispersion and measurement of the complete sample will succeed in just a few seconds even for agglomerating and adhesive powders.

All measurement and dispersion parameters are software-controlled and can be saved as retrievable measuring methods (Standard Operating Procedures (SOPs)). In this way, measurements are reliable and independent of the operator, even if the product and application are changed frequently. Feed rate, dispersion energy, position of the dispersing line and the trigger for the measurement can be reproduced accurately and fully automatically. The dosing procedure, which is perfectly tailored to bridging materials, and the high-performance dry dispersion ensure a high sample throughput with best repeatability for the measurements. The dosing of the powder sample is performed by means of the precision vibratory feeder VIBRI/R, which guarantees the optimum concentration for the measurement in the free aerosol jet through a consistent, controlled product supply.

The rotation of the charging funnel against a static scraper and the use of a double hammer system for funnel and chute help to ensure that all of the product is fed to the measurement. Even with bridging, adhesive sample materials the dosing and dispersion system is emptied without leaving any residue behind, and the risk of cross-contamination is avoided. For larger sample volumes, in addition to the 150 ml model a rotating funnel with a volume of 1,000 ml and a double hammer system is also available. The U-shaped chute is made of stainless steel (just like the funnel) and has a polished surface. Further surface finish options include coatings with conductive or non-conductive PTFE.

The HELOS system can be integrated in an automated laboratory via various interfaces. The control and evaluation software typically receives an ID and a time stamp for a sample from the control system. Based on this, the system calls up a measurement specification, adjusts the measuring and dispersion parameters fully automatically, performs the measurement and reports the results of the measurement back to the control system. In this way, remote controlled measurements can be performed self-sufficiently in automated operation even if there are frequent product and grade changes.

- Particle size and particle size distribution

- For dry, fine to coarse grained, cohesive and adhesive powders

- For analyses in the quality or production laboratory | Also process-oriented

- Sample amount per analysis < 1 mg to 1,000 g

- 7 high-resolution measuring ranges from 0.1 µm to 3,500 µm | R1 to R7T

- True-to-method measurement performance for changing measuring tasks

- Automatic adjustment of all dispersion parameters | Software-controlled

- Dosing system with rotating charging funnel | 150 ml or 1,000 ml volume

- Double hammer system for effective cleaning of funnel and chute

- Remote control of the measurement procedure via TCP/IP or serial interface

- Transmission of results to the control system via TCP/IP, Modbus®, Profibus®, OPC, RS232, RS485 | TXT or CSV file transfer

The modular concept of the HELOS laser diffraction series allows this configuration to be systematically expanded with numerous dispersion units and dosing options to open many more measuring applications.