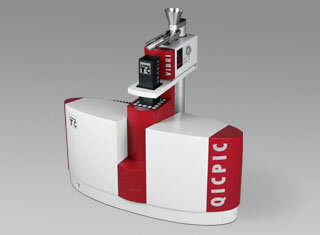

Process-related characterisation of particle size and particle shape for free-flowing powders, fibres and granules from 5 µm to 10,000 µm with dynamic image analysis

The combination of PICTIS & VIBRI unites precise dosing, gentle dispersion and powerful sensing in a versatile and robust image analysis system that is at home in laboratory environments with manual or automated sample loading just as it is in process-oriented on-line installations. The system can be used both for fixed, stationary installation and in a mobile rack for use in pilot plants or at varying measurement locations. Thanks to the use of the GRADIS free-fall dispersion, which is integrated in the PICTIS system, free-flowing and even metastable powders and granules can be gently dispersed and reliably measured. The dynamic image analysis delivers a statistically robust and meaningful characterisation of the size and shape of compact particles from 5 µm to 10,000 µm – or even significantly higher for elongated fibres. Even smallest amounts of oversize and undersize particles or individual particles with special physical properties, such as aggregates, breakage or impurities, can be reliably detected. The high-frequency image analysis close to production supports integrated quality inspections and optimised process control.

The sample, which is fed into the hopper of the precision vibratory feeder VIBRI/L, is supplied with a constant mass flow at a carefully dosed rate into the gravity disperser GRADIS. In the GRADIS fall shaft, the sample stream is accelerated under gravity and the particles are gently dispersed in free fall. The free-fall shaft can be optionally equipped with deflector plates to cause particle-to-particle collisions and particle-to-wall collisions for selective separation of the particles under measurement. After measurement, the sample is optionally disposed of via an extraction system or recycled for further analyses via a cyclonic separation.

The PICTIS system can be flexibly integrated into control systems for processes or automated laboratories via common communication standards such as Modbus®, Profibus®, and OPC (Open Platform Communications) with TCP/IP, RS232 or RS485. In automated operation, the control and evaluation software typically receives an ID and a time stamp for a sample from the control system. The PICTIS system performs the measurement and reports back the measurement results. With changing products, the system calls up a corresponding measurement specification and adjusts the measuring and dispersion parameters fully automatically. In this way, remote controlled or autonomous measurements can be performed even if there are frequent product and grade changes.

Customization to the specific process environment and to the products that are to be measured is achieved in close cooperation with your process engineers and our experienced engineering team. Special designs for regulated environments (GMP) are belong to our portfolio.

- Particle size, particle shape, fibre characterisation

- For free-flowing, coarser or even metastable powders, fibres and granules

- For analyses in laboratories or pilot plants with manual or automated sample feeding | off-line + at-line

- For process-related analyses with suitable sampling and feeding | on-line

- Sample amount per analysis 10 g to 1,000 g

- 2 high-resolution measuring ranges from < 5 µm to 10,000 µm as the upper limit for compact particle shapes | M7 & M8

- Characterisation of slender fibres even with lengths over 10 mm

- Gentle dispersion of metastable products in free fall

- Variable installation for stationary operation or for mobile applications

- Measurement outside the process line under process-related conditions

- Remote control of the measurement procedure via TCP/IP or serial interface

- Transmission of results to the control system via TCP/IP, Modbus®, Profibus®, OPC, RS232, RS485 | TXT or CSV file transfer

- GMP version

off-line functionality with manual sample feed

The versatile PICTIS & VIBRI system can be used for many different applications as a laboratory device with manual sample feed. The process-design of the sensor is ideal for production laboratories or for use in pilot plants (e.g. in the kilo laboratory). The system is either mounted stationary to a wall or frame or in a mobile rack. As standard, the systems are pre-equipped for potential integration into a fully automated at-line laboratory automation system or for coupling to a larger production scale at a later date.

The at-line version of the robust PICTIS dispersion and sensor unit is suitable for automated laboratory operations. The integration in the central control system and the method for feeding back the results are adapted to the existing communication environment. After the automated application of the sample into the hopper of the VIBRI dosing system, all of the required dispersion and measurement steps right up to the evaluation and presentation of results are performed autonomously or via remote control. Rapid measurement and cleaning cycles and regular reference measurements combine to deliver a low-maintenance system that is always ready to perform.

The PICTIS system is operated in a bypass line to the main process stream and is supplied with product samples from the product stream via a suitable sampling system. The precision vibratory feeder VIBRI serves as the interface for transfer of the process sample; with a uniform, regulated product supply it guarantees the optimum sample concentration in the measuring zone of the PICTIS system.