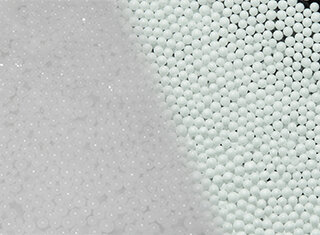

Characterisation of the particle size and shape of dry powders, fibres and granules from 1.8 µm to over 3,500 µm with on-line image analysis directly connected to process

Together with the representative sampler TWISTER, the image analysis sensor PICTOS forms a perfectly coordinated and robust on-line process analysis system with integrated RODOS dry dispersion. The sampler is integrated in the process line, ejects a sample and feeds it directly to the analysis of particle size or particle shape. The interplay between sampling, dispersion and dynamic image analysis enables continuous real-time measurements of dry powders and granules with compact particles ranging from 1.8 µm to 3,500 µm – or even higher in the case of elongated fibres. Even smallest amounts of oversize and undersize particles or individual particles with special physical properties, such as aggregates, breakage or impurities, can be reliably detected. Directly connected to process lines with diameters from 38 mm to 800 mm and mass flow rates of 1 kg/h to over 100 t/h, the representative, high-frequency recording of measured data under process-related conditions enables integrated quality inspection and optimised process control.

For reliable on-line particle analysis, representative and continuous sampling is just as much a prerequisite as the full dispersion of the primary particles. The TWISTER sampler, which is integrated in the process line, scans the entire pipe cross-section on a spiral path and ensures that all regions are sampled with equal weighting. The representative subsample is fed into the process-oriented PICTOS system and it is then dispersed with compressed air in the RODOS injector and measured in the measuring zone of the image analysis system in the free aerosol jet. The information gained in real-time about the particle size distribution or particle shapes can be provided via standard communication interfaces to a process control system for process monitoring or for process control.

In order to adjust the sampling to the product and to the process conditions, calibres of 4 mm, 6 mm and 10 mm are available for the TWISTER sampling tip and for the PICTOS dispersing line. The handling of the extracted sample in a bypass line enables safe and reliable analysis in a closed system. Even toxic or pharmaceutically active substances can be handled practically zero emissions. After measurement, the sample can optionally be returned to the process, disposed of via an extraction system or made available for further analyses via a cyclonic separation.

The TWISTER sampling system can be switched into standby mode, in which it is hermetically sealed against the process and against unnecessary particle ingress. If necessary, due system maintenance or servicing can be performed without interrupting the process. The mechanical systems of the TWISTER are fully encapsulated against the product stream, so no particles can come into contact with moving parts or seals. To clean the sampler and the dispersing line during operation, a blow-back device can be integrated as an option. Sheath flow and air purge ensure that the optical components are kept clean. As a result, the measuring system is virtually maintenance-free and always ready to perform.

Customization to the specific process environment and to the products that are to be measured is achieved in close cooperation with your process engineers and our experienced engineering team. As an alternative to the TWISTER sampler, it is also possible to connect a SCREWSAMPLER, probes or suitable samplers provided by the customer via a clamp connection to the PICTOS. Special designs for regulated environments (GMP) are also part of our portfolio.

- Particle size, particle shape, fibre characterisation

- For dry, fine to coarse grained powders, fibres and granules

- For product temperatures from -20°C to 60°C

- For continuous real-time analyses at the process | on-line

- 2 high-resolution measuring ranges from 1.8 µm to over 3,500 µm | M7, M8

- Dynamic and representative TWISTER sampling in the process line

- on-line measurement outside the process line under process-related conditions

- Statistically robust results based on the measurement of large particle numbers

- Remote control of the measurement procedure via TCP/IP or serial interface

- Transmission of results to the control system via TCP/IP, Modbus®, Profibus®, OPC, RS232, RS485 | TXT or CSV file transfer

- Monitoring of multiple process lines with a single sensor | Multiplex installation

- GMP version

All on-line systems can be optionally equipped with a manual sample feed, which comprises the vibratory feeder VIBRI and a stainless steel hopper. The systems are equipped with a VIBRI platform and the corresponding connections as standard. The hopper is mounted with a clamp connection onto the sensor system in place of the hose line of the sampler. This upgrade enables manual off-line measurements and is also required for re-certification of the systems with reference material. The system is optionally designed for fixed, stationary installation or in a mobile rack for use at changing measurement locations.

In cases where particle size needs to be monitored on multiple process lines, the capturing of measurement data can be done with just one PICTOS image analysis system and multiple samplers installed in the different lines. Sequential sampling provides the sensor with samples from the different lines one after the other via a collector. Fast measurement and cleaning cycles effectively prevent the risk of cross-contamination during processing of the individual samples from different origins.