Using particle size analysis to control the production and quality of chocolate

The industrial production of high-quality chocolate is carried out in a technically demanding process. Cocoa beans from various tropical provenances are used as the raw material for chocolate production. After cleaning, roasting, sterilising and peeling, the cocoa beans are ground into a viscous mass – the cocoa mass. The cocoa mass is then pressed so that the cocoa butter separates from the dry cocoa mass. The fat is then removed from the dry cocoa mass to a greater or less extent and is then available as a cocoa powder with typical residual fat content between 10% and 20% as an intermediate or final product. The cocoa butter is mainly used as an ingredient in chocolate production. The original cocoa mass is sometimes directly used for chocolate bars.

If the cocoa mass is further processed into chocolate, other typical ingredients are added with sugar first and, if necessary, cocoa butter or other fats as well as milk powder, spices, flavours or additives. This chocolate mass is evenly mixed and finely ground in multi-stage rolling mills, so that particularly the sugar crystals, the cocoa powder and other solid ingredients of the chocolate reach the desired degree of fineness. The aim is to create a smooth chocolate mixture that only contains a small proportion of particles larger than 30 microns and no coarser particles larger than 70 microns. However, the particle size does not only determine the sensory pleasure, it also influences the plasticity of the chocolate mass and therefore its suitability for further processing. Finally, the residual moisture is evaporated, the desired aroma developed and the smooth character of the final product created using a mechanical-thermal process – conching.

Quality Control

Very different particle sizes are found in the quality and production control depending on the process stage. The particle sizes range from over 300 microns during pre-rolling to below 30 microns in the final products. The industrial manufacturing process requires a continuous control of the particle size distribution to ensure consistent product quality – both in continuous and in batch production, and particularly at different production sites.

Laser Diffraction in tempered suspensions

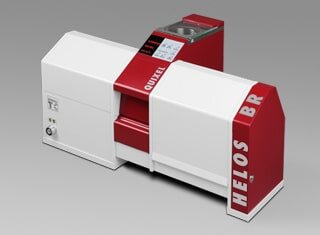

In addition to traditional methods such as screening or measuring using the micrometre screw, laser diffraction is used as a particularly efficient and reliable method for determining particle size distribution. The HELOS laser diffraction displays its strengths in the quick, precise and high-resolution analysis of cocoa and chocolate masses in combination with the temperable wet disperser QUIXEL. The easy setup for measuring routines in the application software makes it possible to establish standard measurement methods for automated, reproducible and user-independent measurement results.

With a volume of 1 litre and the integrated ultrasound, the QUIXEL measuring circuit makes it possible to measure relevant sample quantities for excellent statistical reliability and reproducibility of results – even with coarser samples. The tubeless, direct sample management guarantees excellent resistance to all organic dispersing media and allows for quick, thorough and automated cleaning between measurements. The dispersing media are also used sustainably and efficiently in combination with the optional reprocessing plant LIQIBACK.

Control of incoming dry bulk materials

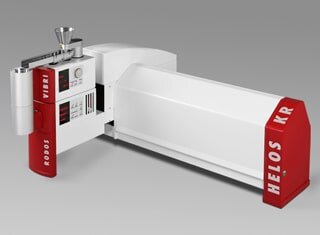

The extension of the modular HELOS laser diffraction sensor to include RODOS dry dispersion means that it is also possible to quickly and reliably characterise other ingredients such as sugar, milk powder, vanilla, hazelnut pieces, shredded coconut or fruit pieces.

- Efficient production and best quality of final product

- Ensuring consistent product quality in various production locations

- Fast, accurate and high-resolution particle size analyses

- Transferable standard measurement methods

- Automated measurement routines

- Stable measurement technology with high availability

- Measurement of optimally tempered samples in organic dispersing media | Sunflower oil, palm oil, liquid cocoa butter, Isopar G

Chocolate ...

... is a highly popular food all over the world and consists mainly of cocoa and sugar. Recipes with cocoa butter, dairy products, nuts, spices and aromas provide greater product variety. Chocolate, as a luxury food, is subject to cultural preferences and is produced in regionally varying qualities that are influenced by the sensory sensitivity of the tongue. While people in Japan prefer very fine and smooth chocolate with an average particle size of around 10 microns, people in Europe like chocolate with an average particle size of 12 microns to 25 microns. 30 microns or more are common in American chocolate. The most chocolate is consumed in Europe and North America. The per capita consumption in some Northern and Central European countries is above 8 kg, while Switzerland is the worldwide leader at more than 10 kg. Chocolate is marketed directly at consumers and as an industrially processed semi-finished product.

Download application notes for detailed information

Forgot your password?

Please enter your username or email address. Instructions for resetting the password will be immediately emailed to you.

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Application strengths

- High statistical significance due to large sample quantities of up to 1 litre

- Short measuring and cleaning cycles with fast automatic emptying, cleaning and filling

- Stable construction | Measurement in process environments also possible

- Rapid homogenisation of the sample thanks to integrated temperature control | Constant viscosity and prevention of blistering

- Option for reprocessing dispersing media

Customer benefits

- Reliable quality control for the best final product quality

- User-independent, reproducible results with high accuracy

- Meaningful measuring results with high-resolution particle size distributions

- Easy method transfer thanks to automation of the measurement process (SOP)

- Consistent product quality at different production locations

- Increase in production efficiency thanks to timely process interventions