Milk powder is used as a wholesome food for infants and is an important raw material for many foods such as cheese, yoghurt, baked goods, confectioneries and chocolate. Compared to liquid milk, milk powder provides the advantage of longer shelf life, lower weight and simpler transport. It is made from different types of milk with a water content usually reduced to about 3% by spray drying. For this, the milk is finely atomised in a spray tower and exposed to hot air. The water content of the milk is evaporated and the dry milk particles are isolated from the air. The bulk material obtained this way is transported, packaged, stored and dosed over the course of further processing. The physical properties of this bulk material, such as the flow properties, dust behaviour, dosing, bulk density or solubility, are affected by the particle size and the particle shape.

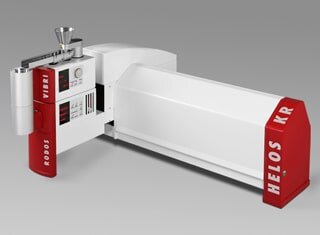

The annually increasing demand for dry milk powder requires efficient use of production capacity and places increased demands on production and quality control. The classic methods for particle characterisation – such as screening – are increasingly being replaced by more efficient technologies. The laser diffraction with the RODOS dry dispersion is becoming the dominant method for determining the particle size distribution in the laboratory or directly in production for the inspection and management of the processes in real time.

Characterisation of the particle shape with image analysis

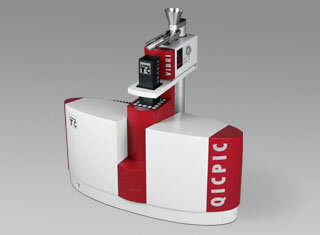

If the particle shape continues to a play a role in the product properties of interest, the dynamic image analysis with QICPIC is applied. Particle shape influences the flow properties and the bulk density of dry milk powder. In addition to various shape-related evaluation modes for a quantitative statistical analysis, image analysis also delivers qualitative views of the particle projections via the representation of individual particles in the particle gallery.

Various evaluation methods are available for describing the particle shape. Feretmin and Feretmax describe the smallest and the largest elongation of a particle across the distance of two parallel tangents (calliper model). The best approximation to the actual volume of a compact, irregular particle arises from the equivalent projection area of a circle (EQPC).

- Measurement of the milk powder in a dry state

- Rapid analysis of large sample volumes

- High sensor sensitivity required

- High measurement frequency

- Efficient measurement and meaningful measurement results

Download application notes for detailed information

Forgot your password?

Please enter your username or email address. Instructions for resetting the password will be immediately emailed to you.

Are you interested in additional content? Please register an account. After confirming the registration link brochures, application notes and other documents on particle measurement will be available for download.

Customer benefits

- Replacement of time-consuming screening analysis

- Precise and rapid inspection of the particle size distribution

- Vivid characterisation of particle shape

- User-independent measurement results

- Less waste production

- Ensuring the desired product properties for fault-free processing and best final product quality

Application strengths

- Automatic and representative sampling

- Almost continuous analysis in real time

- High analysis frequency

- High comparability for laboratory analysis with HELOS & RODOS thanks to having the same core technologies

Customer benefits

- Reliable production control

- Consolidation of process understanding

- Early identification of quality deviations allows timely process interventions

- Avoidance of faulty batches

- Completely automated process management

- Quality control of the final product in real time

- Automatic release procedures